Categories

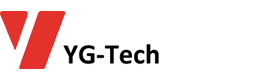

● By using the annular gap discharging method and optional automatic hydraulic system, the compound feed and high starch content feed can reach 40%~60% cooking degree.

● The expander is equipped with a customizable conditioning and retaining system to ensure that the material can be properly pre-cooked under high output.

● Specialized for extrusion of nutritional formula food, deep processing of tissue protein and alternative protein food.

● High torque, large L/D ratio, special food grade alloy material used in the components which contact with raw materials.

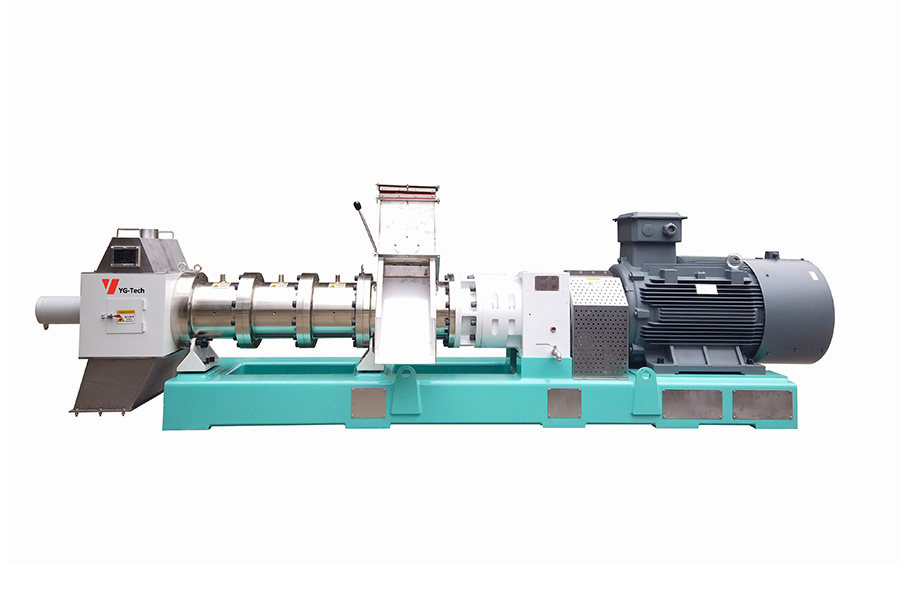

SFSP SERIES HAMMER MILL(Fine Grinding)

● High production capacity and low energy consumption.

● Improved structural strength and more reliable performance.

YGFL Series Vertical Pulverizer

● The use of direct structural drive instead of belt drive , saving energy consumption of 5%-10%.

● The new assembly motor adopts water-cooled mode instead of air-cooled mode, saving 7.5Kw energy (cancel the cooling blade).

● The double feed system makes the material more evenly distributed in the crushing room and improves the crushing efficiency.

● The discharge silo adopts volute structure, which improves the classification efficiency and thus improves the productivity.

YGFP Series Ultra-fine Pulverizer

● Super fine grinding and classifying.

● Specialized water cooling system.

● Suitable for preparation of raw materials of micro-pellet extrusion.

● Efficient and reliable, can replace the vertical pulverizer and work independently.

● High mixing uniformity without residue.

● The discharge door and shaft end are specially designed to ensure no leakage.

Contact Information

BEIJING MODERN YANGGONG MACHINERY SAND T DEVELOPMENT CO.LTD

Building12,Xinggu West Rd Liandong U valley, Pinggu District, Beijing, China

BEIJING YANGGONG MACHINERY JIANGSU R&D AND MANUFACTURE BASE

Building 17, Phase I, Liandong U-Valley Intelligent Manufacturing Technology Park, Yangzhou Economic Development Zone

0086-13910006739 / 15345257920

QUICK NAVIGATION