Categories

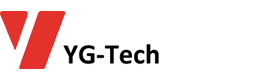

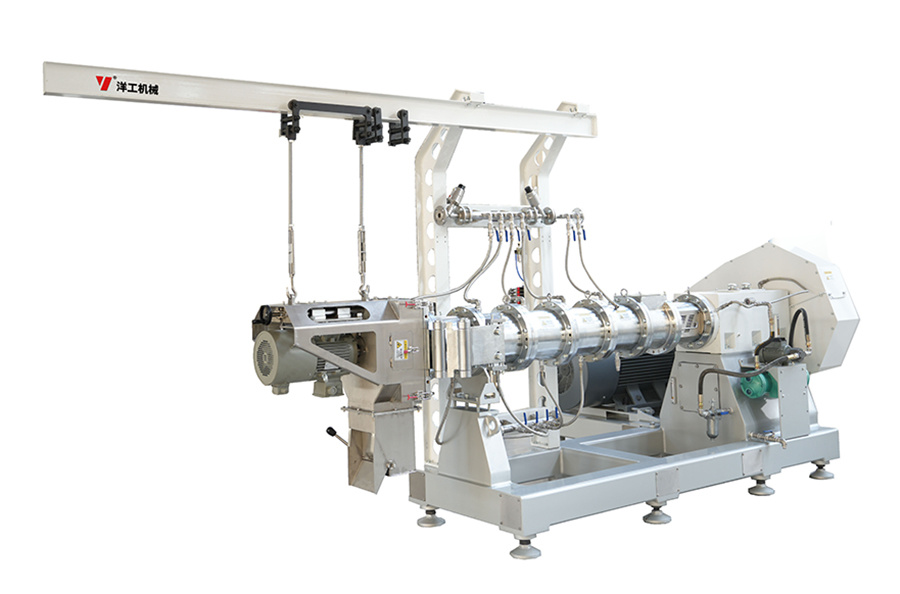

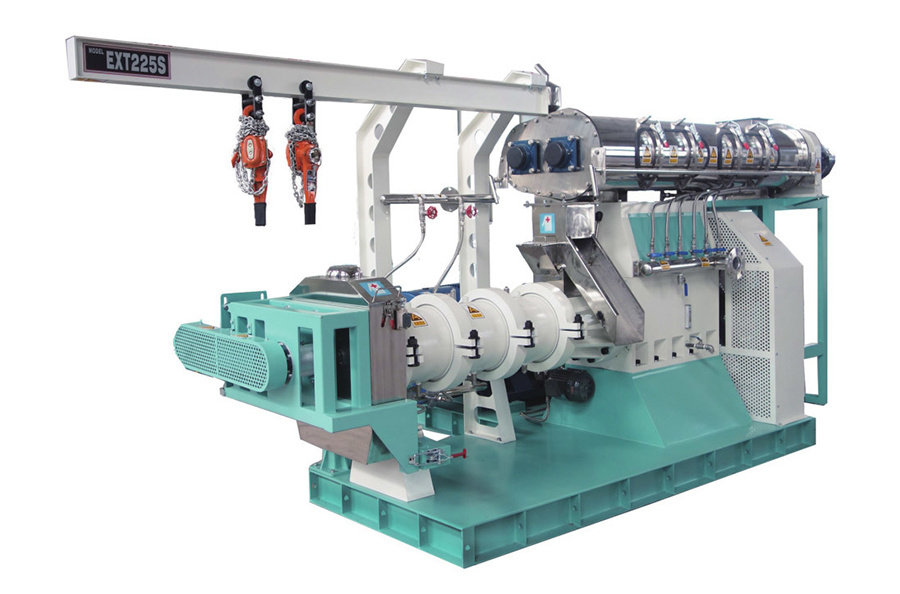

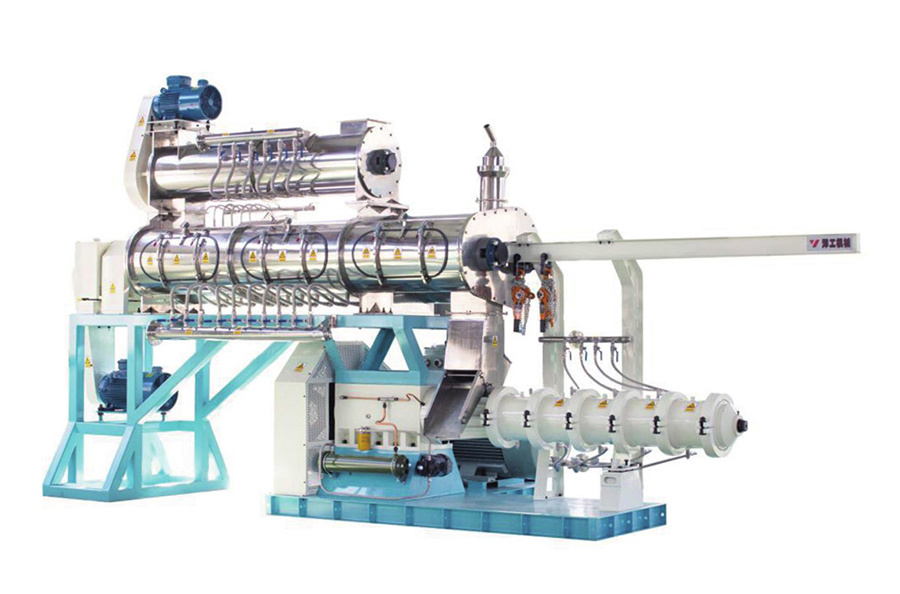

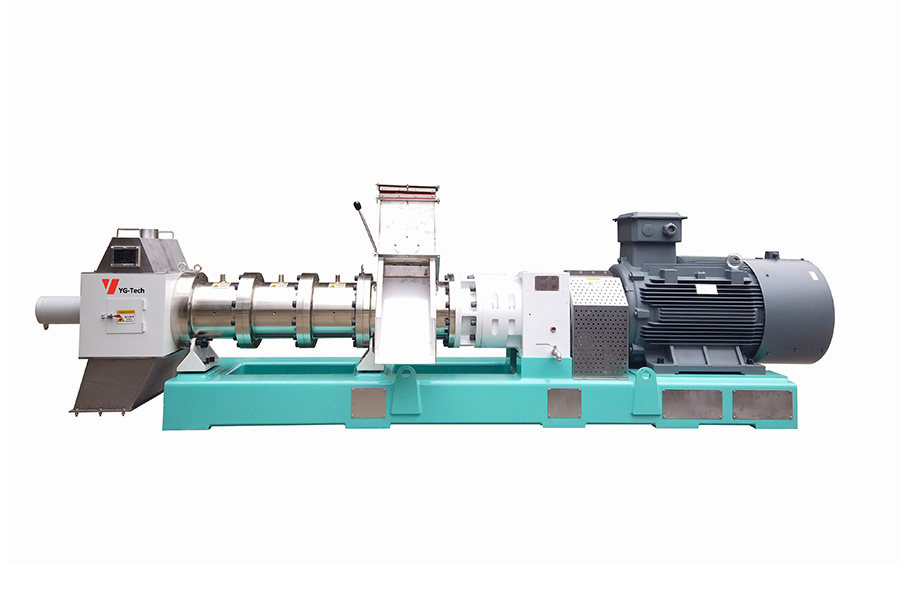

AFE Series Aquatic Feed And Pet Food Extruder

● High efficiency increases the capacity up to 10% to 20%,good stability and reliable, fit for most kinds of formula.

● Advanced R&D center designed specialized die and discharging System, insure the product quality and shape.

● Fit for raw material extrusion, like high starch content, meal, cake and br an kinds of raw material, alternative protein raw materials.

● Good stability and reliable, customized configuration meets different requirements.

● Extruding feed raw materials efficiently without steam condition.

● Good stability and reliable, customized configuration meets different requirements.

● Equipped with large double shafte differential speed conditioner, and it can be equipped with customizable conditioning and retaining system, ensuring all raw materials get well pre-treated.

● High production efficiency; up to 25T/h.

● The antigen can be removed effectively, and the instantaneous discharge temperature can reach 160~ 200 ℃, under the condition of suitable protein solubility, the product can still be produced with high efficiency.

● By using the annular gap discharging method and optional automatic hydraulic system, the compound feed and high starch content feed can reach 40%~60% cooking degree.

● The expander is equipped with a customizable conditioning and retaining system to ensure that the material can be properly pre-cooked under high output.

Contact Information

BEIJING MODERN YANGGONG MACHINERY SAND T DEVELOPMENT CO.LTD

Building12,Xinggu West Rd Liandong U valley, Pinggu District, Beijing, China

BEIJING YANGGONG MACHINERY JIANGSU R&D AND MANUFACTURE BASE

Building 17, Phase I, Liandong U-Valley Intelligent Manufacturing Technology Park, Yangzhou Economic Development Zone

0086-13910006739 / 15345257920

QUICK NAVIGATION